55 kW (76 PS)

350 Nm

4-Zyl / 3600 cm³

Stufe 5

To date, over 3,500 Unitrac models have been delivered. The Unitrac is the all-terrain combination of transport vehicle and equipment carrier - its variety of equipment is just as large as its areas of application. The Unitrac can be used universally from transport to agriculture and forestry, landscape maintenance, to municipal and winter service. More than 10,000 attachments for the Unitrac system are in use across Europe and make both the stepless LDrive models and the switched P5 transporters versatile equipment carriers for year-round use.

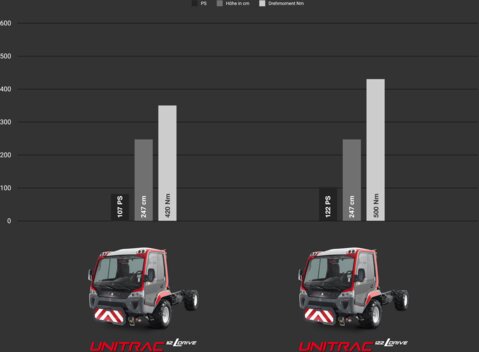

Unitrac P5

Lindner has been producing Unitrac transporters in Kundl for the municipal sector, cable cars and farms for over 25 years. There are currently over 3,500 Unitracs with 10,000 attachments in work across Europe. More than 80 Unitracs are included in the City of Vienna‘s vehicle fl eet alone.

Highlights

Whether for clearing snow, as a sweeper, mower, for disposal or transport—the Lindner Unitrac is a versatile complete equipment carrier: economical and manoeuvrable on the road, gentle on the soil in grassland management and safe off-road. The pioneering technology is equipped with a unique chassis concept and is therefore ready for every conceivable requirement: independent suspension, disc brakes, hydraulic suspension with level control, permanent all-wheel drive, load-switchable differential locks and much more.

Tiltable comfort cab

Optimal all-round visibility: You can see everything: the front working area through the heatable panoramic windscreen and a clear view on the sides through the large glass doors with wide-opening sliding windows. The rear-view mirrors with integrated additional indicators are electrically adjustable and heated. Comfortable equipment: The wide-opening doors provide easy access to the spacious comfort cab. The automatic door opens the rear window upon entry, making it easier to close the door gently with optimal cabin ventilation. The non-slip storage compartments and nets as well as the large cup holder are practical additions.

Split transmission

The CVT stepless transmission used in the Unitrac 112/122 LDrive was developed together with ZF and is produced by Lindner. The transmission is particularly effi cient due to the largely mechanical power transmission with low hydrostatic content in the working/driving range. The Unitrac P5 comes with a fully synchronised 16/16 speed split transmission as standard.

Working hydraulics with variable displacement pump

4-wheel steering

High-performance chassis

The Unitrac chassis concept has already proven itself in over 3,500 vehicles, in grassland management, with cable car and industrial customers and as municipal equipment. Independent wheel suspension and hydraulic suspension cylinders with diaphragm accumulators in conjunction with the rotating part between the front and rear frame guarantee optimum suspension comfort with maximum off-road mobility. Due to the rotating vehicle frame, all four wheels have constant contact with the ground and the highest possible traction. The standard mechanical level control ensures maximum tipping stability in diffi cult terrain. Due to the relatively small spring travel of the system, the upper edge of the loading area is particularly low, despite the large tyres that are fi tted.

Brakes

The vehicle is equipped with a dual-circuit brake system, 2 internally ventilated front disc brakes and 2 rear disc brakes as standard. Less pedal pressure and reduced heat build-up increase comfort and safety. The Unitrac can optionally be equipped with an eddy current brake or a compressed air brake system. The optionally available, patented safety lock acts directly on the service brake and ensures stability on steep terrain.

Unitrac LDrive

To date, over 3,500 Unitrac models have been delivered. The Unitrac is the all-terrain combination of transport vehicle and equipment carrier - its variety of equipment is just as large as its areas of application. The Unitrac can be used universally from transport to agriculture and forestry, landscape maintenance, to municipal and winter service. More than 10,000 attachments for the Unitrac system are in use across Europe and make both the stepless LDrive models and the switched P5 transporters versatile equipment carriers for year-round use.

Highlights

Whether for clearing snow, as a sweeper, mower, for disposal or transport—the Lindner Unitrac is a versatile complete equipment carrier: economical and manoeuvrable on the road, gentle on the soil in grassland management and safe off-road. The pioneering technology is equipped with a unique chassis concept and is therefore ready for every conceivable requirement: independent suspension, disc brakes, hydraulic suspension with level control, permanent all-wheel drive, load-switchable differential locks and much more.

Tiltable comfort cab

Optimal all-round visibility: You can see everything: the front working area through the heatable panoramic windscreen and a clear view on the sides through the large glass doors with wide-opening sliding windows. The rear-view mirrors with integrated additional indicators are electrically adjustable and heated. Comfortable equipment: The wide-opening doors provide easy access to the spacious comfort cab. The automatic door opens the rear window upon entry, making it easier to close the door gently with optimal cabin ventilation. The non-slip storage compartments and nets as well as the large cup holder are practical additions.

Split transmission

The CVT stepless transmission used in the Unitrac 112/122 LDrive was developed together with ZF and is produced by Lindner. The transmission is particularly effi cient due to the largely mechanical power transmission with low hydrostatic content in the working/driving range. The Unitrac P5 comes with a fully synchronised 16/16 speed split transmission as standard.

Working hydraulics with variable displacement pump

4-wheel steering

High-performance chassis

The Unitrac chassis concept has already proven itself in over 3,500 vehicles, in grassland management, with cable car and industrial customers and as municipal equipment. Independent wheel suspension and hydraulic suspension cylinders with diaphragm accumulators in conjunction with the rotating part between the front and rear frame guarantee optimum suspension comfort with maximum off-road mobility. Due to the rotating vehicle frame, all four wheels have constant contact with the ground and the highest possible traction. The standard mechanical level control ensures maximum tipping stability in diffi cult terrain. Due to the relatively small spring travel of the system, the upper edge of the loading area is particularly low, despite the large tyres that are fi tted.

Brakes

The vehicle is equipped with a dual-circuit brake system, 2 internally ventilated front disc brakes and 2 rear disc brakes as standard. Less pedal pressure and reduced heat build-up increase comfort and safety. The Unitrac can optionally be equipped with an eddy current brake or a compressed air brake system. The optionally available, patented safety lock acts directly on the service brake and ensures stability on steep terrain.