THE COMPANY

The Tyrolean family company Lindner has been

successfully asserting itself on the market for 75 years.

The Tyrolean family company Lindner has been

successfully asserting itself on the market for 75 years.

Lindner tractor factory - successful in its niche.

Be innovative and use niches: The Tyrolean family company Lindner develops and produces tractors and vans for alpine mountain and grassland farming, cultivated agriculture and municipalities. The 253 employees in Kundl in Tyrol produce 1,200 Lintrac and Unitrac machines every year. The technology forge generates half of its sales on export markets such as Germany, Switzerland and France. The focus of all innovations is the goal of optimizing the work of customers. That is why Lindner relies on versatile, compact and clean vehicles. The company, which has been producing tractors since 1948, places particular emphasis on digitization. Lindner has developed the TracLink system, which recognizes devices precisely and adjusts them perfectly. Automated systems guarantee efficient and precise work.

Family company

Innovation and a pioneering spirit were already corporate principles for our grandfathers that still make our tractor factory successful today.

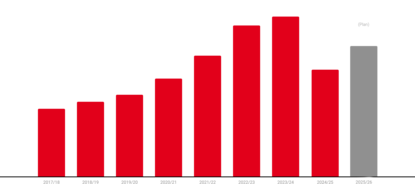

Lindner produced the first tractor more than 75 years ago. Today, the third and fourth generations are continuously developing the family business side by side. Since spring 2024, David Lindner is managing director for finance, human resources, marketing and sales, customer service and digitalization of the company based in Kundl. His cousin Christoph Lindner is responsible for vehicle assembly and the repair shop since 2023. Stefan Lindner continues to manage technology, purchasing and parts production.

Since the founding of the Lindner tractor factory, the company has been based in Kundl in Tyrol. In addition to the company headquarters - the technology center - both the factory and the Lindner innovation center are located here. Since 2018 there has also been a location in France with the competence center in Blotzheim.

The new technology center in Kundl was opened in 2008. It is the interface between Lindner, its customers and international development partners. The building is constructed as a low-energy construction and is equipped with a computer-controlled shading and air conditioning system. The development hall, the technical offices as well as marketing and sales are housed there. A groundwater heat pump provides heating and cooling. The ventilation of the rooms is controlled via presence and CO2 detectors.

In 2014, Lindner opened its new innovation center in Kundl as a multifunctional sales, training and customer center, where particular emphasis was placed on sustainable construction. The building materials come from the region, and the energy-saving components mean the building almost reaches passive house standards. A photovoltaic facade generates environmentally friendly electricity for lighting with particularly economical fluorescent tubes and LED spotlights. A highlight in the new building is the Lindner Museum with an innovation gallery: There, Lindner shows highlights from the company's 70-year history. The spectrum ranges from vintage tractors to exciting interactive elements.

In 2018, the Lindner France competence center was officially opened in Blotzheim in Alsace. Blotzheim is located in the border triangle of France, Switzerland and Germany and in the immediate vicinity of the Euroairport Basel Mulhouse. Lindner thereby expanded its activities in the French-speaking markets.

Quality and innovation from Tyrol

A new Lindner tractor rolls off the production line in just two days: the chassis is assembled on the first day. Painting is done in the evening - the paint is dry by morning. On the second day, all lines, cables and hoses are laid, various additional equipment is attached and the cabin is put on. As soon as the tires are mounted, it goes on to the end of the line where all settings are made and the vehicle is prepared for the final inspection. Over 250 Lindner employees produce around 1,200 tractors and vans a year with up to 200 hours of manual labor per vehicle.